I. Short Details

II. Technical Details

I. Short details

ELEVATED ROLLER COASTER TRANSIT SYSTEM (Patented)

Technology is a mean to provide safe, clean and efficient mobility services for people and goods.

We've all been there at one point or another--stuck in bumper-to-bumper traffic, horns honking, palms sweating, blood pressure rising. With the increasing amount of time a person spend in their cars each day, road rage is a phenomenon we've all been affected by.

Customers for travel and transport make informed choices about modal mix considering their needs for comfort, timeliness, security and affordability. The synergy with other modes and effective use of the road infrastructure ensures fluid flow on the network.

We offer a tyre based train made of very light modern coaches. The chassis of coaches strengthened more than Railway Coaches shall be placed in tandem to run on smooth concrete track like Roller coaster.

Being exposed to Roller Coasters on daily basis he developed and patented lightest weight, elevated, rapid transport systems at most economical price in contrast to monopolized railways identified on date as the only public carrier. The system that the promoter has developed is also suitable for mountains and sea ports and for transportation of goods rapidly in congested cities and for intercity as well.

No body thought of roller coaster as transport system but in fact this can be most suitable alternative to Railways from 1/5th to 1/10th the cost of railways and can fit in most congested roads of old and new cities, especially in developing countries . The Roller Coaster requiring minimum width can be most safe transport system. It will remove all buses and also trucks from roads of congested metros and towns by setting up goods stations outside the cities to transport all goods to different destinations of towns by elevated Roller Coasters

No body can say that a Roller Coasters which works day and night continuously carrying millions of visitors every day in Amusement parks will refuse to run over the roads in cities. In one shot, Roller coasters will be able to solve the most complex problem of public transport by using same bus routes and same bus stops existing in cities by running over the foot paths or by sides of roads. Not only this, the system will reduce all emissions of gases from buses and trucks in cities. This system can also replace railway and other transports for inter city travel as well at much lower costs.

The Roller Coaster Technology scored on two Strong points

- Load factor

- Safety factor

1. Load Factor

The most important factor for any transport mode, be it on ground or elevated or underground that contributes to its cost is its dead weight and the weight of its supporting structure or super structure.

If the dead weight of a system can be reduced, the cost factor of the system automatically reduces.

This is what exactly is done by Roller Coaster.

It is only Roller Coaster which can have the lightest dead weight.

2. Safety Factor

Box shaped Coaches or even open coaches which can turn twist, go up down ,left or right , not only that, even up side down have found to be the system as safest and surest way to travel with thrill and excitement.

As compared to Railways and Mono rails, whose the dead weight of single coach carrying just 50 -70 passengers weighs 75 tonne to run on plain flat track. The dead weight of coach used in roller coaster can be as low as 2 tonne for same 50-70 passengers.

The Mono Rail also has similar dead weight as railways.

M/s CVH WALZE LTD has indulged during last few years in various infrastructure projects like High Speed trams for Delhi, Mass transit system for Vizag, Hyderabad, Vijayawada and Pune etc.

His company was the first in India to sign MOU cum work Order with Pune Municipal Corporation to set up first Elevated Roller Coaster system for 14 km costing US$ 70 million in year 2000 to bring in new era of transportation at most economical cost but at the time, there was no example of setting up commercial spaces above stations, so the request made by us not grated then which resulted in delay. Now having seen Metro Rail in Delhi with Malls at stations, the system can go to places.

DOWN LOAD POWER POINT PRESENTATION

2. Technical Details

TECHNICAL DETAILS

EXTRA LIGHT RAPID TRANSPORT SYSTEM

A ROLLER COASTER SYSTEM HAVING TRACK RECORD OF

SAFETY, RELIANCE, EFFICIENCY AND ECONOMY

BOLD INITIATIVES HAVE MADE AMERICA THE WORLD POWER

INDIA AND CHINA NOW ARE ON FAST TRACK TO CATCH UP IN INFRASTRUCTURE SECTOR AND ARE LOOKING FOR BEST SOLUTIONS.

THERE IS A RACE GOING ON IN THE WORLD TO FIND SOLUTION TO THE DEAD WEIGHT PROBLEM IN THE MASS TRANSPORTATION SYSTEMS. THE HEAVY DEAD WEIGHT IN PRESENT SYSTEMS UNDULY INCREASES THE COST.

We have found the solution to this very problem so now we can offer a most economical, most safe and most efficient system which can work independently or in thin lanes or work as feeder services to Metro.

This solves once for all, all the problems of city transport.

A Roller Coaster can be three ft wide- four feet wide train having nylon rollers/ rubber tyres as wheels which can run on steel track or RCC track :

- These trains can also be compared to small trains being run for hills, a meter gauge trains or broad gauge trains for heavy load traffic requirements. The basic technology remains the same.

- These trains can also be 6ft -10 ft wide and can have look of bus coaches with high capacity at par with railway

BRIEF ABOUT OUR SYSTEM

We offer you a tyre based train made of very light modern coaches. The chassis of coaches are strengthened more than Railway Coaches by extra grip of wheels. The coaches are placed in tandem to run on smooth straight concrete track like Roller coaster.

The system is most economical, most safe and most efficient than any other system existing any where in the World as on date as this is the only system which can use the lightest coaches as compared to any other system in the world. This can also be compared to other tyre based systems like Mono Rails, Public Mover System or Tyre Based Railways.

PROJECT DETAILS

WHAT IS OUR SYSTEM?

By using Roller Coaster system we can use the lightest coaches and end the race to reduce dead weight in transport systems :

STEP BY STEP DESCRIPTION OF SYSTEM .

STEP 1 We will cover the open coaches of Roller coaster to provide cover to people from Sun Rain, wind etc.

STEP 2 We will widen the coaches , keeping the technology as it is

STEP 3 We will replace the steel track with RCC track to reduce the noise level in Roller coaster

STEP 4 We will replace the nylon rollers with Rubber tyres for smooth run on RCC

WE WILL BE SIMPLY REPLACING THE OPEN COACHES USED IN ROLLER COASTERS WITH MINI BUS BODIES OR BUS BODIES WITH THEIR CHASSIS STRENGHTHENED WHILE KEEPING ALL OTHER SYSTEMS AND TECHNOLOGY AS USED IN ROLLER COASTER .

Now the question arises as to why we and not the rest of the world could think of or implement this most safe mode of transport in cities while having seen its performance for last 100 years in Amusement Parks in train form carrying 1000s of visitors in each round.

The answer is simple that a Roller Coaster, a Mono Rail or a Public Mover system can not change Tracks easily as is possible in Railway system, a very important factor required for mass transportation system. This is the reason that Railways have maintained its monopoly over other systems while Mono rails or Public Mover systems are confined to single track to run to and fro or on a circular track only. Any train stopping on the way will stop the entire system.

This will be a story of past now. We have now found the solution of track changing in Roller Coaster, obtained Patent and further filed for another improvement in our existing Patent. Now we can bring this system out of Amusement parks and offer this System for cities.

- Our system is bigger roller coaster which has a history of safety for last 100 years.

- It can also be termed as tyre based Roller Coaster or lightest railway in place of steel wheels on steel track, using every thing as it is in railways.

- By light weight coaches and further additional of solid tyres binding the track not only from top but sides and bottom as well to make our system super safe, non derailing or over turning ever.

SYSTEMS IN COMPARISON TO OUR SYSTEM OPERATING THE WORLD OVER

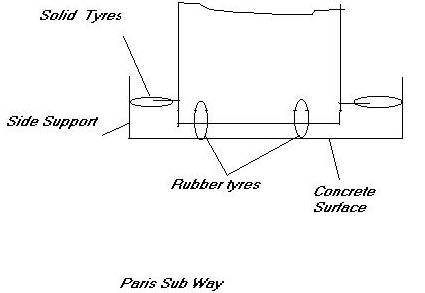

- PARIS SUB WAY : uses rubber tyre based wheels in place of steel wheels used in other sub ways with additional solid rubber tyre side wheels which guide the trains to the direction as set for the trains. The side tyres slide on vertical planks installed on two sides of train. The use of rubber tyres brings in quick acceleration, deceleration and efficiency as compared to railways using steel wheels on steel track which is very loosely placed and skids easily requiring extra ordinary heavy dead weight of coaches to be in place at speed (as shown in here under)

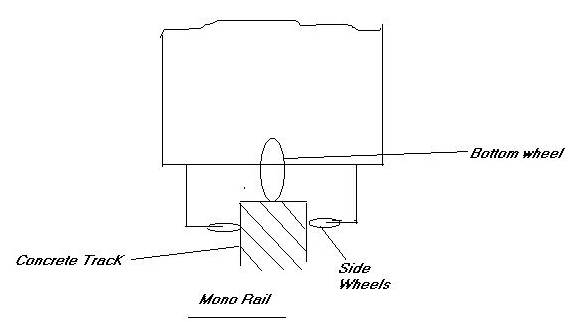

- MONO RAILS: having very heavy bus type coaches like railways to avoid up liftment on speed, uses only one rubber tyre below the coach which runs and drives the train on a concrete beam while two solid rubber tyres support the train from tilting by running on two sides of the same beam. Such systems are working at only a few places because of low stability and high maintenance cost. Can not change tracks very easily, an important factor for mass transportation, so runs on a circular track or to a fro way on a single straight track. ( as per sketch below)

- PUBLIC MOVER SYSTEM : Very heavy bus type coaches to avoid up lift ment on speed, has rubber tyre wheels as in bus but two solid rubber tyre wheels below the top wheels sliding on two sides of concrete track has track changing problem so confined to circular or to a fro motion only.(as per sketch)

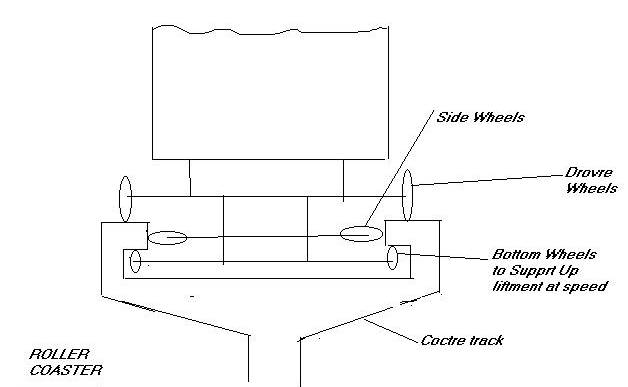

4 ) ROLLER COASTER: Uses nylon Rollers or rubber tyre wheels at top, sides and bottom of the track, thus binds the coach from all sides and also the track from all sides . This makes this system most safe as compared to all the existing systems of the world as on date. This is the only system which can rise up to thousands of feet and then drop even in open coaches not straight but in zig zag, twist turn, left right even up side down but still safe sound and perfect from all angles.

ROLLER CAOSTER has as three sets of wheel at one point unlike any other system. This arrangement makes it most safe to run in zig zag, up down, left right, even up side down, so if Roller coaster has to run on straight smooth surface that too of concrete, what is the difficulty for it at all.

PRESENT SCENARIO OF DEMAND FOR TRANSPORT

Metro Project (elevated Railways) have the most prohibitive costs of Rs 120 crores per Km ($ 25 million per km ) and requires to subsidize the operations later on, that too with the kind of financial state the world is in at present.

If world happen to get more facilities at economical cost, that too with much more safety factors, it is unconceivable as to how many will jump on the band wagon to implement such projects not only in India but the World over once it is installed by any visionary.

This is exactly what we are offering to the world through our R&D and the prototype already made, tested and shown to lot of people in the trade. The prototype is a bigger Roller Coaster.

COMAPRISON IN PRESENT PUBLIC TRANSPORT SYSTEM AND ROLLER COASTER SYSTEM

Do you know that Buses cost just Rs 1.5 crore per km ($ 3 00 000 per km)

- A bus carries 50 sitting passengers, carries 1000 passengers per day

- In ten round trips of say 10 km or total length of 20 km

- For 300000 passengers on any route like Metro we need 300 buses

- Costing 30 crores at Rs 10 lakhs per bus or $6 million at $20000 per bus

- Rs 30 crores/ 20 km = Rs 1.5 crore per km 6million/20000=300000 per km

As compared to METRO RAIL which cost Rs 120 Crores per km ($ 25 million per km ) for the same purpose being implemented the world over. Similar are the costs for other similar modes of rapid transport systems developed on date like Mono rails and Public Mover systems described later.

- A train coach weighs 75 tones and carries as many passengers as a bus which weighs Just 3 tonnes.

- If we use Roller Coaster technology which is the safest technology carrying 100s of people in open or lightest coaches .By just replacing the open coaches with bus coaches the Roller coasters in bigger form can replace all other modes of transports and in smaller form can run in small cities, smaller lanes and also in congested areas at much less cost as well and completely solve the public transport problems of the world.

THE NEW SYSTEM OF ROLLER COASTER IS

- Most efficient rapid transit system

- At much less cost than Railways

- With more passenger carrying capacity than Railways

- Even the idle lying old buses of STATE TRANSPORT CORPORATIONS ( Just the shells) can be run in train form on electricity OR CNG with no pollution at all.

- Our system being 10 times efficient than buses can be viable at bus tariff, not requiring any subsidy as required in metro.

- The new system will cost from Rs1 5 Crores – Rs 40 Crores per km.($3 million to 7.5 million

- For lesser traffic requirements or for thinner roads and lanes , smaller versions of the system at much lesser costs can also be put in place to solve all the problems of public transport not only for bigger cities but small cities as well.

WHAT WILL OUR SYSTEM LOOK LIKE?

To make it simpler to understand ,the system can be considered as

- Several light weight coaches say buses running in tandem to form a train with little modification of chassis of existing buses, can move on ground, under ground or on an elevation on concrete track. This train can replace railway coaches or metro rail coaches.

- This train also has the Track Changing facility to move in various directions thereby being more flexible than the systems restricted to loop travel only.

- It can provide the same or more passenger carrying capacity as possible in Light Railway System or METRO

- It offers maximum safety possible in the system as compared to railways as the technology is based on Roller Coasters which have the highest safety record as compared to Railways where derailments are daily occasions .

- Being light in weight, it can take turns much more easily than Light rail.

- It is more economical than Light Railway System.

- Being rubber wheel drive, there is least noise pollution as compared to Railways

- Being rubber tyre drive it is possible to apply sudden brakes and acceleration as well as deceleration is quick which makes it possible to run more trains per hour as compared to Railways

PROTO TYPE

This transport system was researched extensively and was then tested on the Prototype for two years. Further research innovated track changing in this mechanism thereby making it more suitable for the public transport. We obtained Patent on the technique and offered the project to various cities. The prototype was dismantled after tiring tests and trials.

AWARD OF PROJECT BY PUNE MINICIPAL CORPORATION

We were the first in India to sign first elevated transport in India. After duly considering technically, financially and from all angles and after viewing the Prototype, Pune Municipal Corporation approved our project from Kothrud to Telco , a total strech of 14 km at the total cost at present market price of 420 crores ($ 90 million)with first phase of two km single line from Deccan Gymkhana to Null Stop point Karve Road in Pune which is the hub center of the city and most viable route in the city and had agreed as per MOU cum agreement signed between us to start the project immediately and had also agreed to extend the route after first phase is taken up. We requested the Corporation to allow us to build commercial spaces above the stations but there was no precedence in the country for that but now having seen Malls on stations in Delhi Metro, the project can go places.

COMPONENT DETAILS OF OUR SYSTYEM IN COMPARISON TO SIMILAR SYSTEMS

1. COMPARISON OF BUS AND TRAIN PARTS.

Let us start explaining our system step by step.

ANY RAPID TRANSPORT MODE HAS FOLLOWING PORTIONS.

1 A bus or truck or train has four portions primarily

- A very light body in case of bus but open body or no body and just the plat form in case of truck sufficient to last for 20 years or more.

- A train has heavy body. chassis strong enough to last for 50 years

- A suspension system requiring some repairs in say 5-10 years time

- Drive mechanism be it Petrol, diesel or electric.

Now let us take up the job description and history of each component

A . BODY

- We have not heard in last 100 years if a body of any bus has fallen apart from the chassis while carrying 100 -150 passengers in each and every bus few in side and lot over the roof in developing countries.

- Where as every bus in its life span of say 20 -30 years travels continuously day and night, hour after hour for years together not only on routes in cities where speed can not go beyond 60 km per hour but on high ways where speeds ranging from 70 -100 km per hour is routine, for which each bus and especially if there is a rough driver, it encounters

- Sharp Turns

- Sudden Brakes

- Ups, Downs

- Ditches

- Rough Roads

- Sudden Sliding Of Bus On The Muddy Surfaces Beyond Tarred Roads Having Ditches, Up Down Mould,

- Stepping On Stones And Then To Ditches etc

- Moving Up On Hills On Steep Slopes And Sliding Down The Hills etc.

While bus carries passengers equal to appx 100 passengers weighing about 3 tonnes , the truck carries loads up to 20 tones on an average with no body at all or body or platform only and encounters the same obstacles and hurdles as the buses on roads

There are some trucks which not only carry loads but army tanks and 40 tone containers to hills, deserts and rough roads etc.

B. THE CHASSIS

Now we come to chassis, it is this chassis which takes care of and ultimately carries all kinds of loads and passengers as explained with body of bus, truck or platform on it and is as strong as the chassis of Railway coach or goods train coach and is made of 250 mm c channel.

The difference between the chassis of bus and chassis of train is simply in terms of the extra length required by the train chassis to take care of momentum of various coaches in tandem and is made of 250 mm I girders as in buses, sufficient to take care of 50 coaches of goods train with each coach carrying a load of appx 55 tones or a live load of appx 2700 tones.

C. THE SUSPENSION SYSTEM

We have on hand the details of suspension of buses as well as the trains with their performance history of 100 years and the results have been excellent for all these years.

There have been innovations in field of suspension systems but primarily the comfort levels have not changed drastically over the years.

D. THE DRIVE MECHANISM

There have been great innovations as far as the drive mechanisms are concerned right from petrol to diesel, electric or CNG or LPG gas drive etc but the buses and trains moved from day one to date at less or high speeds with less pollution or more pollution.

The over all difference between the bus and train lies in dead weight. A Railway coach needs heavy dead weight because of loose connection of steel wheel with steel track having carved track and carved wheel to provide minimum of contact width to reduce the friction level so that smaller power is required to run the trains but heavy dead weight requiring much more materials than buses make railway a very costly proposal and increases the risk of derailment.

A bus because of more wider rubber tyres having much more friction element requires very light dead weight and costs much less and is much more efficient in terms of quick acceleration and deceleration.

The problem of congestion and pollution only brings in the question of putting trains at elevation to solve solution of public transport and if we can put the same buses in discipline form at elevation in Roller coaster form, we can not only reduce the cost of public transport but also bring in revolution of a kind.

NOW WE COME TO OUR SYSTEM

We increase the strength of chassis and put bus coaches in a Roller Coaster form rather than open coaches running at present.

1 ) We don’t primarily propose to do any thing else but ply the same buses as running on roads but to run on better smooth concrete surface always rather then rough roads of India, ditches, ups downs, stones and what not as explained above.

Now to simplify further the mater we are here under taking up the questions and answers:

Q: a) Will same buses already tested and tried for last 100 years running on rough and tough roads with ditches and mud and what not explained above, refuse to run on better surfaces of smooth concrete created by us on elevation in track form.

Ans : No

Q. b) Will the chassis of buses do any harm if its chassis is strengthened better than the chassis of goods train which is competent to take loads of 50 coaches with load of 55 tones in each coach is incorporated for buses also.

Ans. No

Q. c) Will the buses have any harm or refuse to run if the tyres are not allowed to go off the track by binding the chassis with two side wheels , while there are no ditches, rough surfaces etc.

Ans. No. we simply discipline the movement in right direction of track

Q.d) Will the buses have any harm or refuse to run if we add an another wheel below the track so that the buses do not run up wards at speed and that too at a meager speed of just 40-80 km on an average

Ans. No, we are just disciplining the movement on plain surface and not allowing the bus to go here and there except sticking on the line of smooth concrete track and not allowing the bus to jump and nothing else.

If we look at the changes carried out and suggested by us ,we can simply understand that visibly there are no major changes and with smooth surface of concrete track the buses will be far more comfortable than running on roads and beyond on ditchy mud etc. Using much more stronger chassis than one used in Goods train which takes care of all the forces required at speed and while braking ,it will be simply a smooth sail for the train made of bus coaches in place of Railway coaches and the binding of wheels will require much less power than Railways and buses on road and with smooth track the transport of the world will become much more smooth and sail well.

The system being proposed by us is simply the buses running in tandem in disciplined form with less efforts and more comfort than running on roads as explained above.

We are sure our explanation above will make you understand the basic principle that we have followed.

HIGH LIGHTS OF COMPONENTS

- Chassis of train

- The body of bus

- The suitable suspension

- The drive mechanism which is simply the electric drive but can be CNG as well

- Run in Roller Coaster way the most simple

- The most safest of all the drives as on date

- Has history of safety of last 100 years

- The buses are more secured

- Have to exert far less being not only on smooth surface but far less jerks, jumps and side movements because of least tolerances of side wheels and lower wheels in contrast to trains having lot of side jerks and side acceleration.

- We don’t stop at that but provide uni- unit, uni directional movement of train on one track which means that only one train can have pass between each station and as soon as one train leaves a station the track behind gets de-electrified and as such no train can travel in the stretch unless the same train leaves the next station.

- Cost most economical

- Saving time frame in running

- Less time required for braking and acceleration.

- No danger of derailment as body is secured from all angles and no loose wheel runs as in trains which often derail.

- Viable at present bus fares

The speeds will also be changed according to the requirements, like on turns the trains will have different speeds and on normal straight tracks the speeds will be different which makes the system totally comfortable as the tolerances which are kept bare minimum do not allow side acceleration and jerks on turns and for this reason that we have never heard in last 100 years or so that any Roller Coaster has gone off the track where as we daily hear of trains derailment here and there.

We have the history of Roller Coasters which is what we are proposing in simple bigger form with 12 wheels for each coach at four points of two axles in place of four wheels for buses and trains, eight for mono rails and public mover systems.

COSTS INVOLVED IN VARIOUS TRANSPORT MODES

| Item |

Cost |

Const Time |

Displacement |

Can go on bus route |

Neighbour hood facility |

Capacity |

Metro Rail |

Rs 120 cr per km

$25million per km |

5 yrs for 10 km |

Displaces the existing traffic route |

No |

No |

40,000 pph |

Mono rail |

Rs 100 Cr per km

$20million per km |

--Do_ |

---Do-- |

---Do-- |

No |

10,000pph |

Our system |

Rs 15 cr per km -40cr per km

$3-8 million pe km |

2 yrs for 10 km |

No |

Yes |

Yes |

From 5000pph -40000pph |

FEATURES AND FACILIES OFFERED

While formulating cost structure we offer following features and facilities.

FEATURES

1. A Roller Coaster can be thin train which can run on the

- Foot paths of roads or

- Wider train to run in the center of roads above the center verge of roads or over foot paths as well

FACILITIES THAT CAN BE CREATED AT DIFFERENT COSTS USING ROLLER COASTER

| COST |

FACILITIES |

Capacity |

Coaches size |

No of coaches |

Rs 15 cr

$3 million |

On ground const. |

5000pph |

6ftx20ft longx6.5 ft high |

5 |

Rs 20 cr

$4 mllion |

Partly on ground/partly elevated |

10000 pph |

7ftx30 ftx6.5ft high |

7 |

Rs 30 cr

$6 million |

elevated |

20000pph |

-----Do--- |

10 |

Rs 35 cr

$7 million |

elevated |

30000pph |

8ftx40ftx6.5ft high |

15 |

Rs 40 cr

$8 million |

elevated |

40000pph |

8ftx40ftx6.5 ft high |

20 |

IMPLEMENTATION OF PROJECT

We do not need Rs 75 crores (US$ 15 million)or more to implement this technology for display in first place as is required in other technologies.

We have already made a Proto Type, tested, tried and run it for Two years in our factory. (Copy enclosed). If we can create prototype on our own cost, we hope any state government can very easily take up following exercise.

We are offering tested tried and proven system for implementation. The governments can straight away start implementing the project which can be set up in shortest possible time and at least cost but as alternative

Now for any city, all that we need, is for the Govt. to hand over one of mini bus or a large bus for us to modify its chassis to make it our engine and run it on a concrete track/steel track as required for Roller Coaster. Once the success story is there for all to see and the Engine has run for a few days, more bus shells can be added in tandem.

OUR EXPERIENCE IN HANDLING VISITORS

We have been running Roller Coasters for last 23 years in Delhi carrying thousands of visitors every day without any break or holiday and manufactured Roller Coasters for others in the country as well without any accident or mishap of any kind and the same is the history of this train every where in the world so where is any doubts for this system for implementation in cities now after we have found track changing methodology and obtained Patent for the system.

OUR EXPERTISE TO UNDERTAKE MANUFACTURING OF THE SYSTEM

We have vast experience in manufacture of various equipments for Amusement parks including Roller Coasters which carry hundreds of thousands of people every month in each equipment and millions of visitors every year.

The manufacture of Amusement park equipment was initiated by us as pioneer in India in 1988 after setting up first Amusement park of India Appu Ghar in Delhi in historical time of 46 days in 1984 with all imported equipments .

The Amusement park Equipment involves the most sophisticated technology which includes mechanical, electrical, hydraulics, pneumatics, electronics etc. and was monopoly of Italy and Germany before.

We have manufactured 100s of equipments for 11 Amusement parks set up in different parts of the country strictly under our personal supervision millions of people are using these equipment every year.

The most sophisticated equipment out of all other equipments manufactured by usAnd tested over the years on live loads for last 11 years was TELECOMBAT which involves seating of 50 people in 25 gondolas which revolve at the end of 25 ft long arms having hydraulic and pneumatic systems to move the arms up and down from 3 ft above ground level to 50 ft above. All the arms are fixed on a geared wheel which revolves around a central pivot arm while the arm it self rises above the ground and also all the hydraulic and pneumatic systems are attached to central wheel itself. The gondolas revolve, the arms revolve and also the arms go up and down. Not only that but each gondola has electronic gun which has an aim in front of it on other gondola in Succession. As soon as the person in each gondola shoot the gun and as it hits the target the gondola in front immediately falls down and then starts rising in succession.

The idea of explaining the above equipment is simply to provide you the information ofthe kind of technology that we are exposed to and that too for the first time that we manufactured equipment which was never ever manufactured before. |